As we take extra precautions to ensure the well-being of our employees, VIEW high-performance metrology Sales and Support remain open for business. Read more

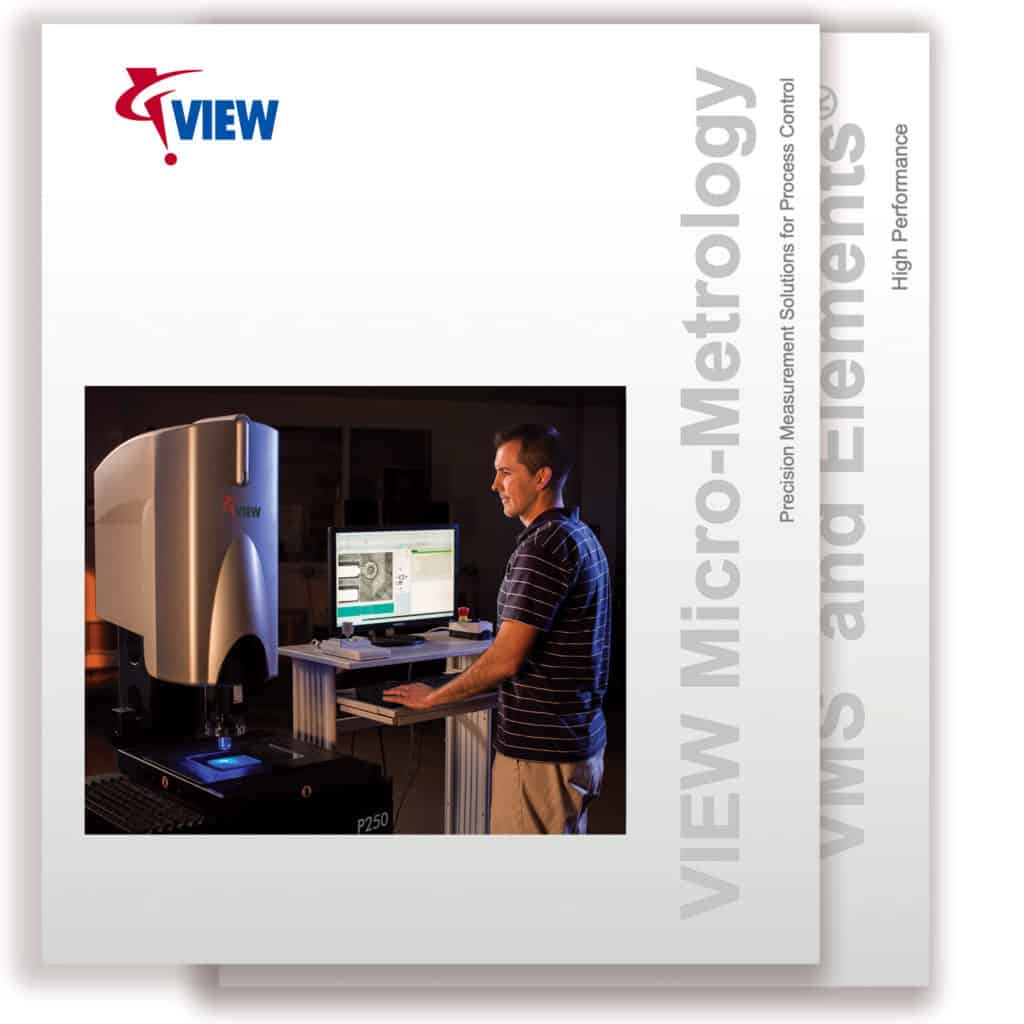

Optical Metrology Systems

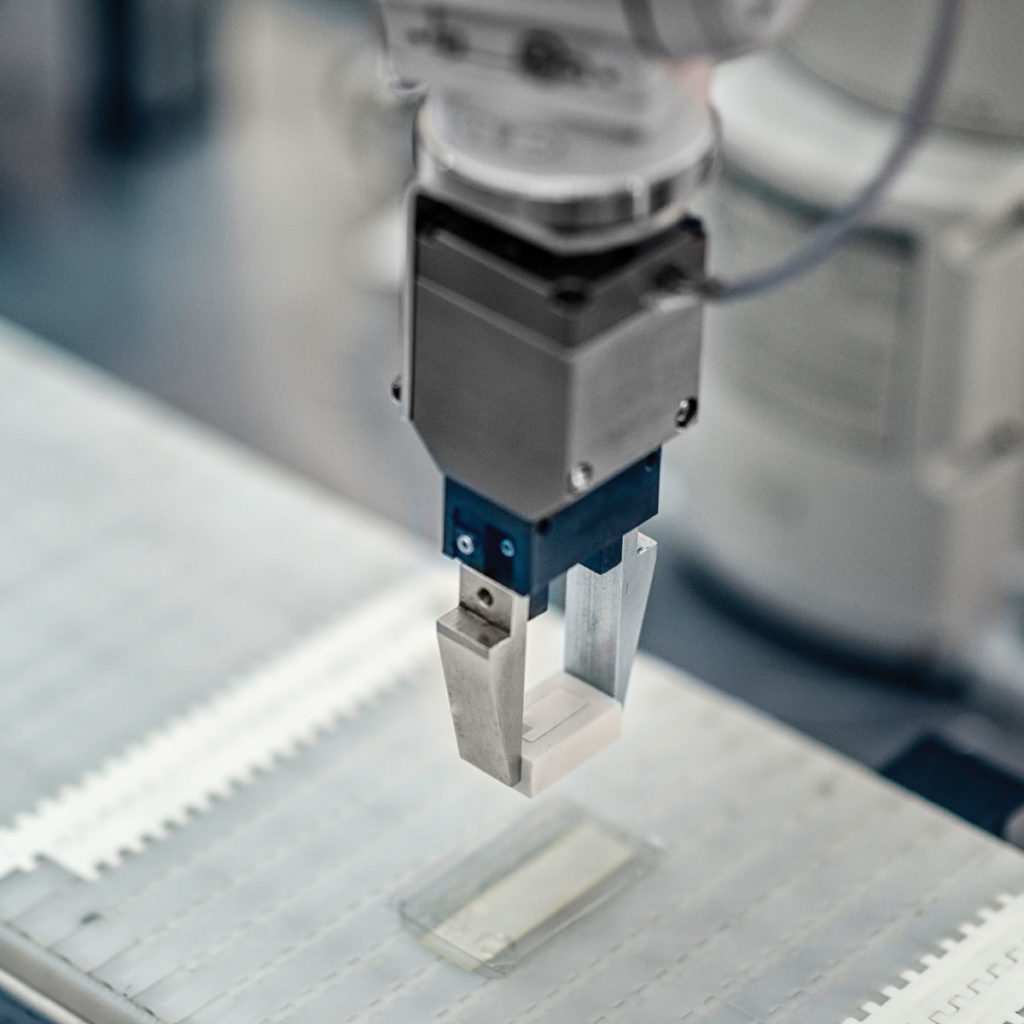

For critical dimensional measurement VIEW offers a full line of optical metrology systems for wafer, photomask, slider, MEMS, semiconductor package, HDD suspension, probe card, and micro-component process measurements.

VIEW Vision News

Keep up to date on the latest in the industry.

The most important metrology technology news, developments and updates with insightful how too and tips. Coverage includes metrology systems hardware, software, …