Improving throughput is a priority for companies around the globe and one of the best ways to do that is by using Continuous Image Capture technology. This is a technology that allows the machine to take images without having to stop the stage for every image. This is done by continuously moving the stage and flashing the lights whenever an image needs to be taken. These flashing lights have given rise to the nickname of “Strobe”.

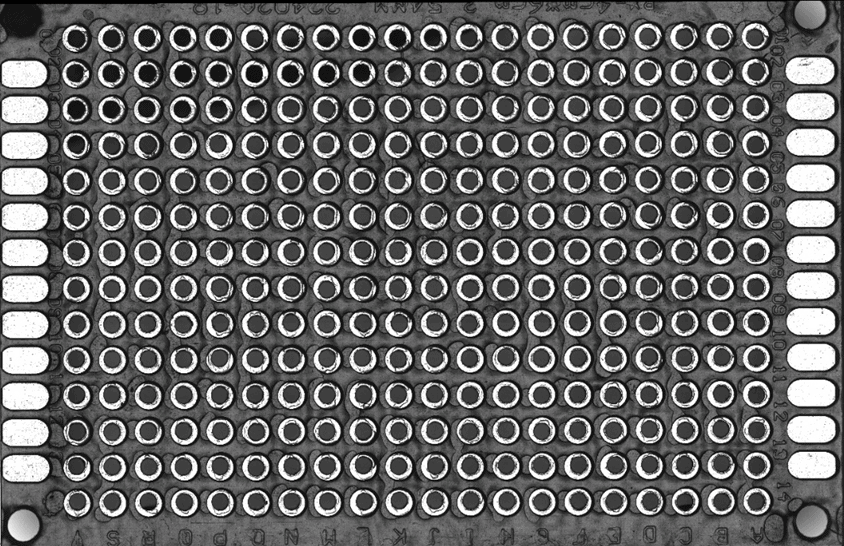

Strobe technology can be used to improve throughput dramatically for certain applications. The best applications for strobe are ones with a multitude of densely packed features on the same plane. For example, the part shown below can be measured in less than half of the time it would take using traditional move and measure.

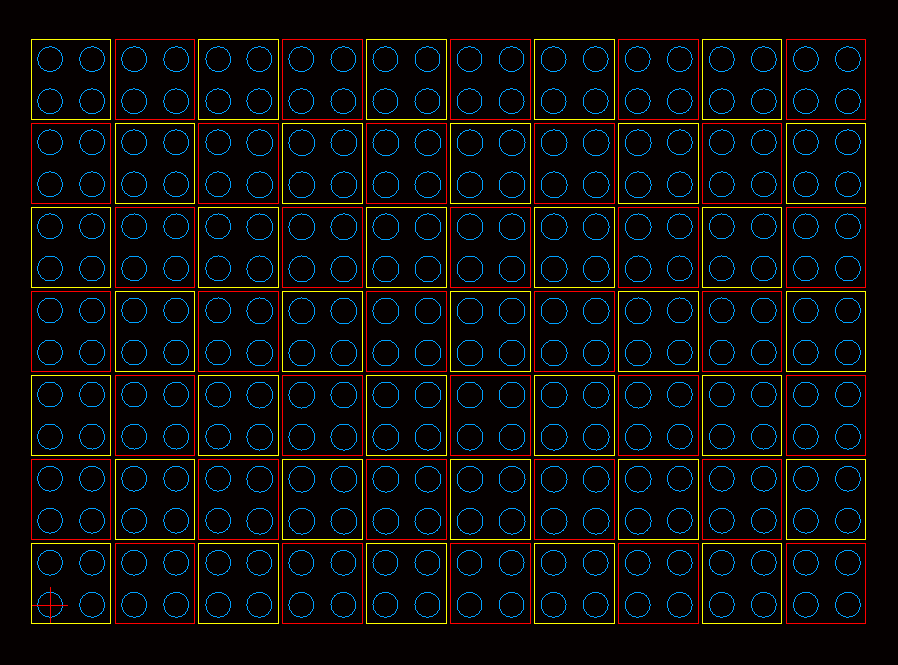

This part has 280 holes and, with a 1X lens, 4 holes fit into a single field a view. To measure the entire part 70 images would need to be taken which means that with traditional move and measure this would require the machine to move, stop, and take an image 70 times.

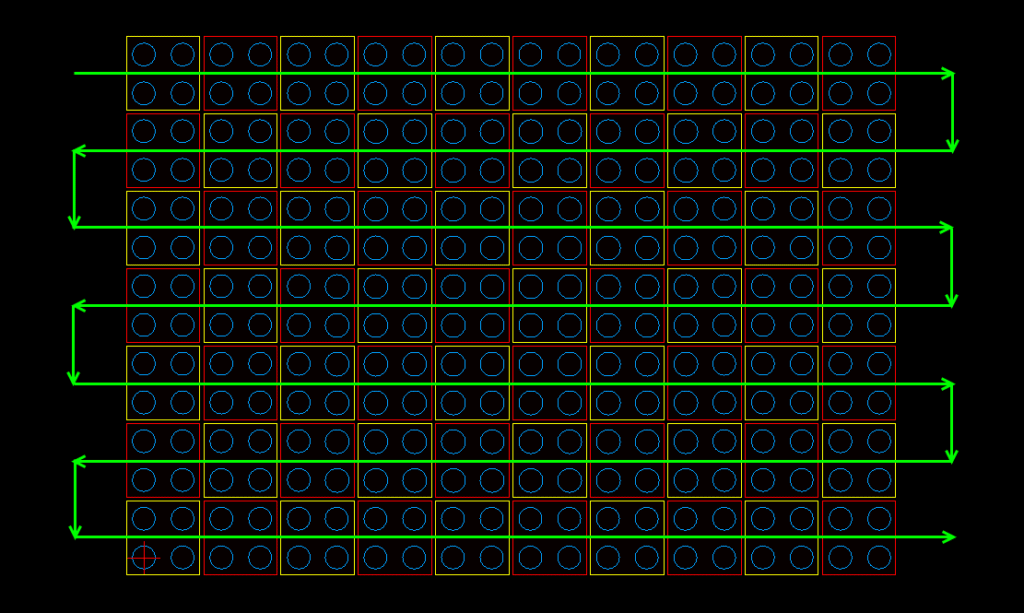

With continuous image capture, images can be captured without stopping the stage. This allows the images that need to be captured to be grouped up into rows or columns. By being grouped in a linear fashion, all of the images in a single row or column can be captured during a continuous stage move along that line. This can significantly decrease the amount of time it takes to acquire all the necessary images.

In this case, the part can be split up into 7 rows which reduces the amount of movements needed to capture all of the fields of view which, in turn, reduces the amount of time needed for the measurements. For this part, it would take around 20 seconds to measure this with traditional move and measure but with strobe the part can be measured in under 10 seconds. A video of this part being measured with continuous image capture can be seen on our YouTube page.

A 100% percent increase in throughput is not uncommon for continuous image capture applications but even greater increases have been seen. Parts that have thousands or even hundreds of thousands of features can see throughput increases of up to 500%.

If you believe your application is a good candidate for continuous image capture give us a call or send us an email and we can set up a demo.