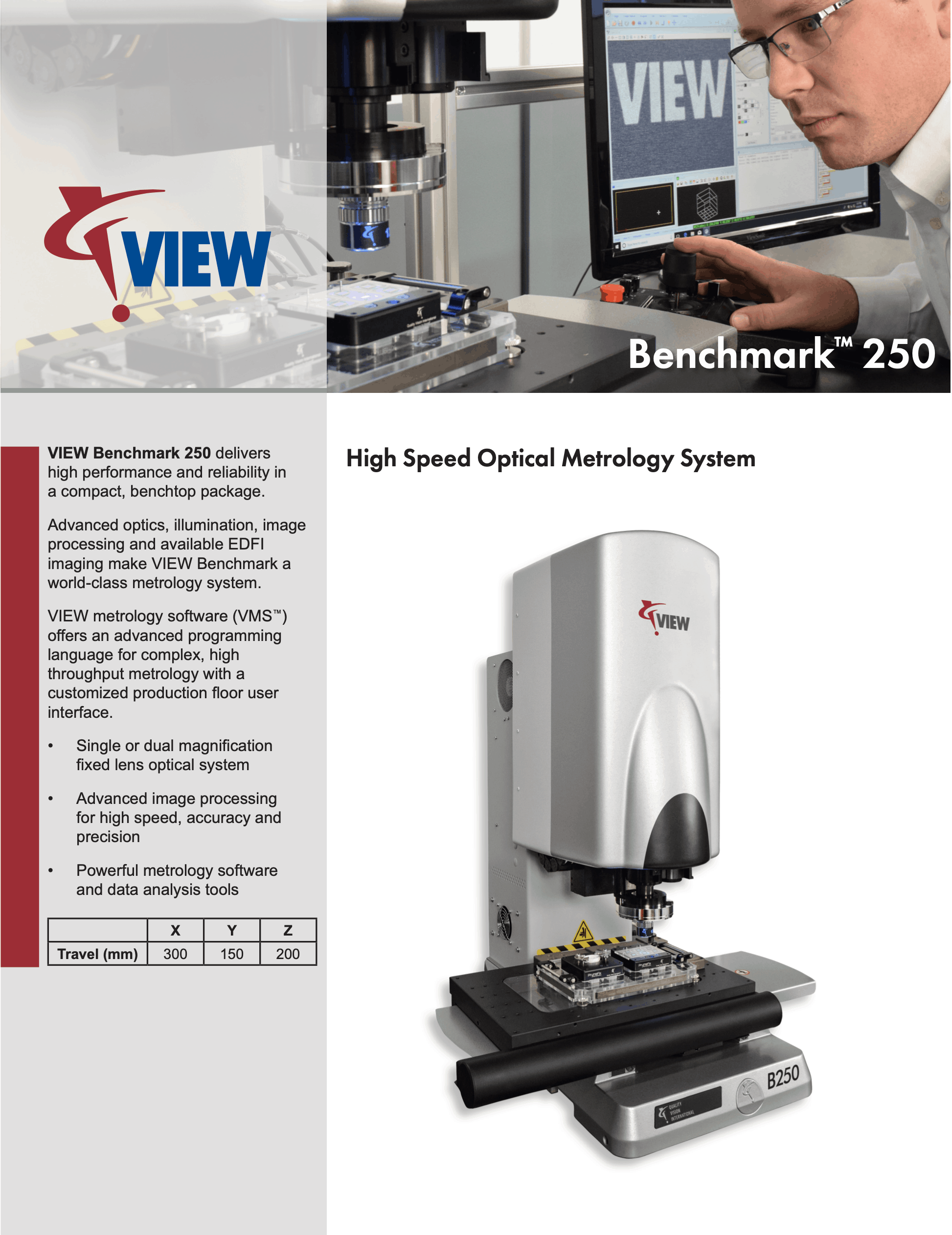

Benchmark 250

A compact, high-accuracy dimensional metrology system.

The VIEW Benchmark™ 250 is engineered for high accuracy in a compact benchtop configuration complete with VIEW’s dual magnification optics and metrology-grade construction.

The Benchmark 250 is designed for use on the production floor to provide precision measurements for process control. Its compact size and powerful software make the Benchmark 250 a versatile measurement system that can be easily configured as either a dedicated gauge for critical dimension measurements or as a general purpose vision measurement system for routine quality monitoring.

Standard

Optional

XYZ Travel

300 x 150 x 200 mm

Load Capacity

25 kg

Imaging Optics

Single magnification, fixed lens optics with VIEW 1X back tube and VIEW 2.5X objective lens

Dual magnification fixed lens optics with VIEW 2.5X objective lens. Optional Objective Lenses: 0.8X, 1 X, 5.0X, 10X, and 25X

Metrology Camera

Standard: 2.0 megapixel (1628 x 1236), digital, monochrome

Color and other camera configurations are optionally available

Illumination

Standard: Programmable LED illumination system for coaxial through-the-lens surface light, below-the-stage backlight, and multicolor ring light with motorized incidence angle control

Grid Autofocus System

Sensor Options

Through-the-lens (TTL) laser

Rainbow Probe ™ off-axis white light range sensor

Measurement Modes

High Speed Move and Measure (MAM)

Continuous Image Capture (CIC)

FEATURES

The Benchmark 250 is well suited to measure many types of components, including molded plastic parts, machined parts, electronic assemblies, semiconductor packages, fiber optic components, disk media substrates, recording head dies, or semiconductor wafers up to 150 mm in diameter.

The Benchmark 250 operates with one or more of VIEW’s standard metrology software packages: