VIEW systems support a variety of laser sensors for height / depth and surface profile measurements. Both through-the-lens (TTL) or offset mounted lasers are available. The primary factors dictating the use of a given laser sensor include the sensor’s measurement range, resolution, spot diameter, working distance, and ability to work with specular or diffuse surfaces.

QVI Rainbow Probe Sensors

High resolution non-contact measurement – Innovative Rainbow Probe analyzes the optical spectrum of reflected light to measure surface height changes

High resolution non-contact measurement – Innovative Rainbow Probe analyzes the optical spectrum of reflected light to measure surface height changes- Measures where other sensors cannot – Rainbow Probe easily measures transparent, translucent, fragile, liquid or easily deformable surfaces

- The right probe for your application – A range of CL-series and RP- series probes are available, each with a unique measuring range, working distance, axial resolution, accuracy, and spot size

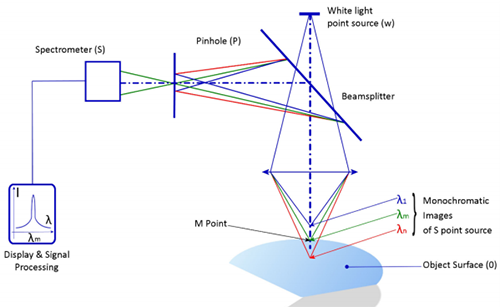

The optical principle of chromatic confocal imaging is shown in the following setup:

An incident white light pinhole is imaged through a chromatic objective into a continuum of monochromatic images along the Z-Axis, thus providing a “color coding” along the optical axis.

When an object is present in this “colored” field, a unique wavelength is perfectly focused at its surface and then reflected into the optical system.

This backscattered beam passes through a filtering pinhole into a spectrograph, which determines the wavelength which has been perfectly focused on the object, and then accuratley determines its position in the measuring field.

The confocal chromatic imaging gives access to reliable, accurate, and reproducible dimentional measurements with extremely high resolution.

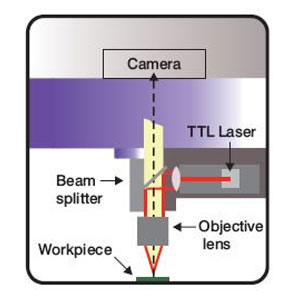

Through-the-Lens (TTL) Laser Integrated Laser Options

VIEW’s on-axis TTL laser shares the same optical path as the system’s video cameras. Laser light travels through the imaging optics to the surface being measured, and is then reflected from the part surface back through the optics to a laser sensor.

This laser configuration allows measurement of recessed surface features or those features adjacent to vertical surfaces. It provides rapid (<0.5 second) auto-focus capability, accurate single-point Z-height measurement, and rapid (up to 10,000 points/second) 3D surface scanning. With a spot size smaller than 10 microns, Z-height resolution of 0.1 micron, and effectiveness on both matte and specular surfaces, the TTL laser extends VIEW’s vision system versatility.