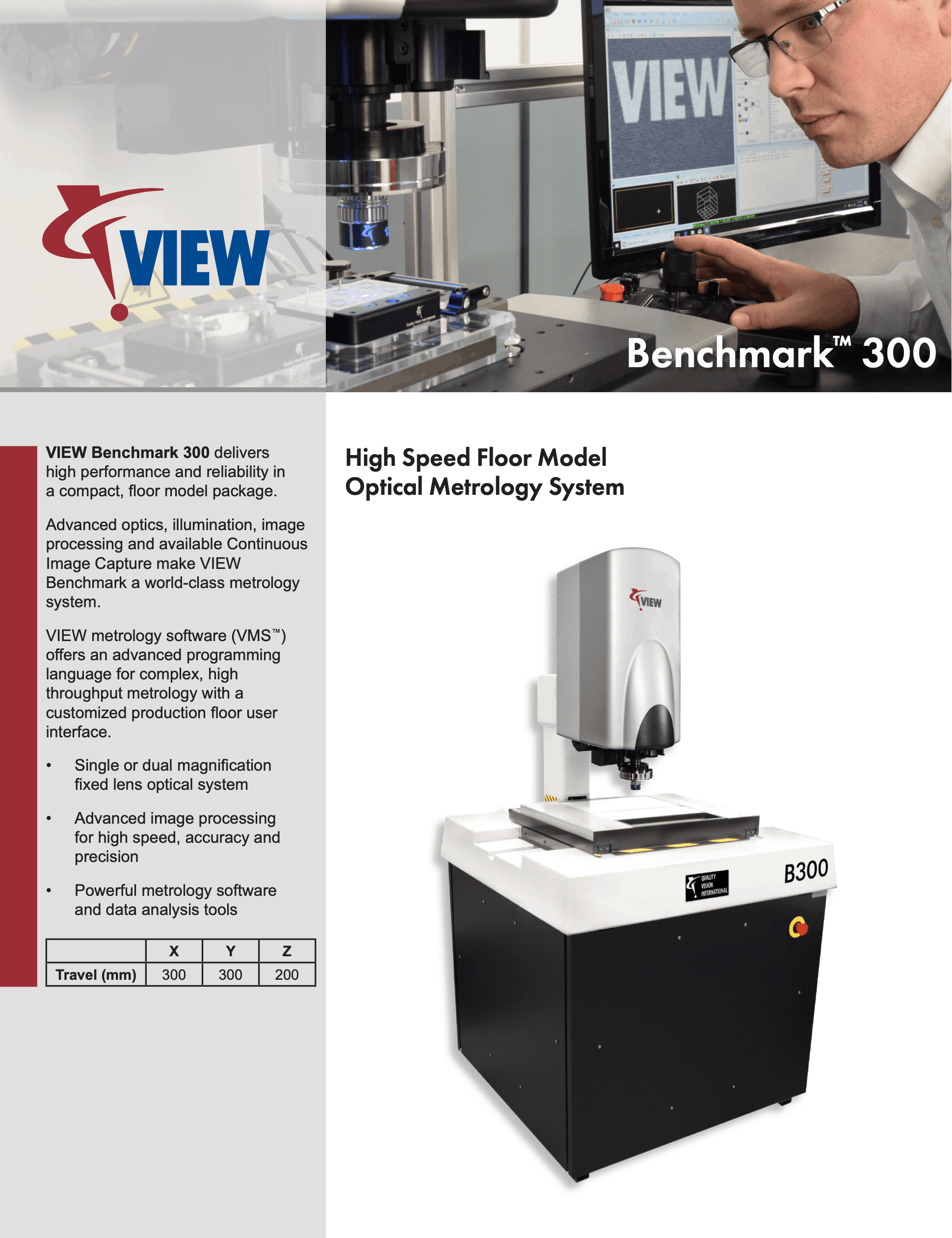

Benchmark 300

High Performance Floor Model Optical Metrology System

The VIEW Benchmark™ 300 is engineered for high performance and reliability in a floor model package. Advanced optics, illumination, image processing, and available Continuous Image Capture make VIEW Benchmark a world-class metrology system.

A VIEW system designed to process parts up to 300x300mm in a compact, floor model platform. The Benchmark 300 is designed for use on the production floor to provide precision measurements for process control. Its stage is ideal for medium format metrology applications that require high throughput, accuracy, and the precision you expect from VIEW.

Standard

Optional

XYZ Travel

300 x 300 x 200 mm

300x300x200 mm

Load Capacity

30 kg

Metrology Camera

Single magnification, fixed lens optics with VIEW 1X back tube and VIEW 2.5X objective lens

Dual magnification fixed lens optics with VIEW 2.5X objective lens. Optional Objective Lenses: 0.8X, 1 X, 5.0X, 10X, and 25X

Metrology Camera

Standard: 2.0 megapixel (1628 x 1236), digital, monochrome

Color and other camera configurations are optionally available

Illumination

Standard: Programmable LED illumination system for coaxial through-the-lens surface light, below-the-stage backlight, and multicolor ring light with motorized incidence angle control

Grid Autofocus System

Sensor Options

Through-the-lens (TTL) laser

Rainbow Probe ™ off-axis white light range sensor

Measurement Modes

High Speed Move and Measure (MAM)

Continuous Image Capture (CIC)

FEATURES

The Benchmark 300 comes standard with:

- High resolution single magnification optical system

- 2.5X microscope objective

- 0.1um scales

- Programmable ring light (PRL)

- Multi-function hand-controller

- PC-based system controller.

- VIEW Metrology Software (VMS), which combines high-level functionality with ease of use in one system.

The Benchmark 300 special options include:

- Enhanced accuracy with 0.05um scale resolution

- Pulsed backlight for Continuous Image Capture (CiC) applications

All of the standard VIEW hardware and software options are also available on the Benchmark 300, including:

- Dual Magnification Optical System

- Grid Autofocus with Ronchi or Dot Grid Projector

- 0.8X, 1X, 5X, 10X, and 25X front objective lenses

- Through-the-Lens (TTL) Laser

- MicroTheta Rotary Table

- Rainbow Probe™

- Industrial Digital I/O

- Temperature monitoring

- Elements Cad to Measure Software

- Continuous Image Capture (CiC)

- Area Multi-Focus Package

- Advanced Image Processing Package