What is AMF™ Area Multi-Focus?

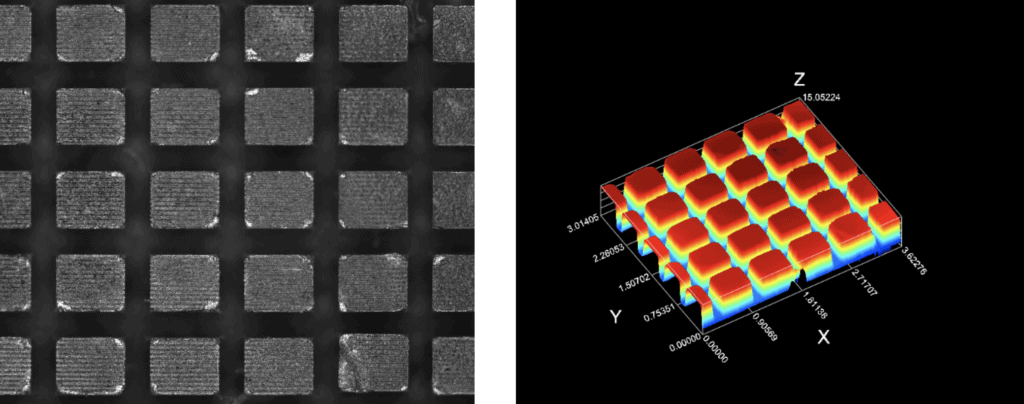

AMF is a technology that creates high-resolution 3D images using machine optics. The technology works like autofocus but rather than finding a single XYZ point, AMF will create an entire 3D image. Below is a graphic of how area multi-focus works. Multiple images are taken during a Z pass and the images are analyzed for focus. The most in-focus sections are taken from each image and put together to create a 3D image.

When should it be used?

When should it be used? AMF offers a high-throughput alternative to single point focus or laser surface scanning. The most common use for AMF is to measure multiple Z heights for features that fit in a single field of view (FOV). With AMF, all the Z heights can be gathered in the amount of time it would take to do single autofocus.

See the example below of apart with multiple features of height in the FOV. A single AMF produces all the Z data needed to measure the heights of the features. VMS utilizes image processing tools for feature segmentation, feature extraction, and height calculation.

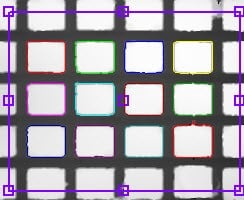

Feature segmentation in VMS is accomplished by first displaying the 3D dataset as a 2D grayscale height map and then using standard 2D tools to define feature areas of interest (AOI). This technique can also be useful for locating features when traditional edge finding is insufficient. This is all done in a few seconds using a single Area Multi Focus.

Below is a 2D height map of the previous 3D dataset with blob finder results showing the AOIs being located. The data for each AOI is then extracted and processed separately to determine the height of each.

Other Uses

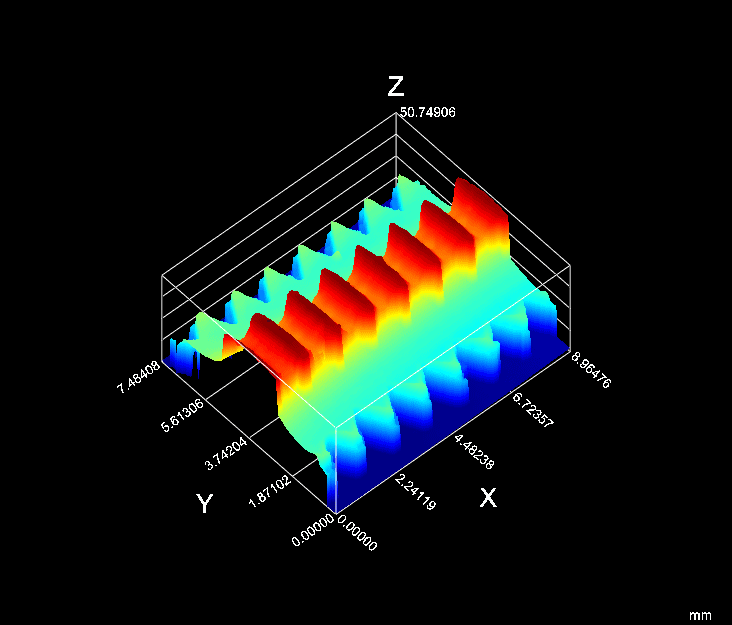

AMF is used for true 3D measurements such as plane angles or spherical radii. AMF can be used in lieu of a touch probe or laser to make these measurements for high contrast surfaces. AMF’s ability to take thousands of points in a single pass allows it to take certain 3D measurements much faster than other types of sensors. Below is an example of a screw tap measured using AMF. A large portion of the tap can be measured in a single pass and from that image the teeth angle and pitch can be calculated. In just a few seconds a wealth of information can be gathered on a part like this using AMF.

A short video of this application being run can be found on our YouTube page.